Connecting local-grown cedar lumber to create a large space

It is a facility newly built in a hilly sports park to mainly practice martial arts. The two parallel large roofs are build up with elegant curved surfaces, and their appearance can be compared to a Japanese sword. It also corresponds with the surrounding mountain range and the dome of the adjacent stadium to form an excellent building landscape. The roof frame is made of cedar lumber produced in Oita Prefecture. In order to procure a large amount of wood without waste, the wood was classified into four types based on properties and used in the right places. For designing, we used VPL, which formulates the rules of structure to incorporate into the 3D model of the computer. The structure and design were verified interactively, and a rational and beautiful roof shape was thoroughly investigated.

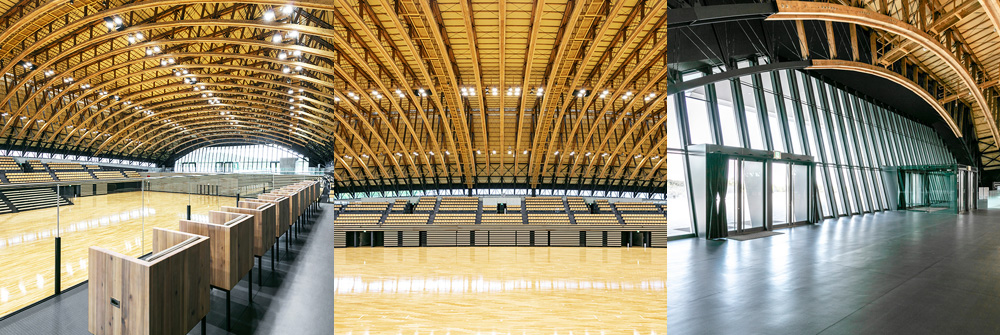

Interior of entrance hall using Beppu bamboo work

A 30 minute drive from the center of Oita City leads to Oita Sports Park. The 253 hectare park site on hilly land includes a comprehensive stadium, Crasus Dome Oita, which served as the venue for the 2002 Soccer World Cup and the 2019 Rugby World Cup, as well as other facilities, including a soccer and rugby ground, a baseball ground, and tennis courts. The new addition is the Crasus Martial Arts Sports Facility. The facilities consist of a main stadium, which can be used for various indoor games in addition to martial arts, and a martial arts stadium dedicated to martial arts such as judo and kendo, and the two are arranged in parallel. The main stadium is 70 x 100 m in size, which can accommodate 4 courts of basketball, 5 courts of volleyball, 2 courts of handball, and 8 courts of judo and kendo at the same time. On the other hand, the martial arts stadium is 28 x 100 m and can be divided into 3 parts. On the first floor, there is an entrance hall named “Earth Floor for Interaction” where traditional local materials such as Beppu bamboo work, Hita sugi (Japanese cedar), and Kunisaki Shichitoui (tatami-mat material) are used for the interior.

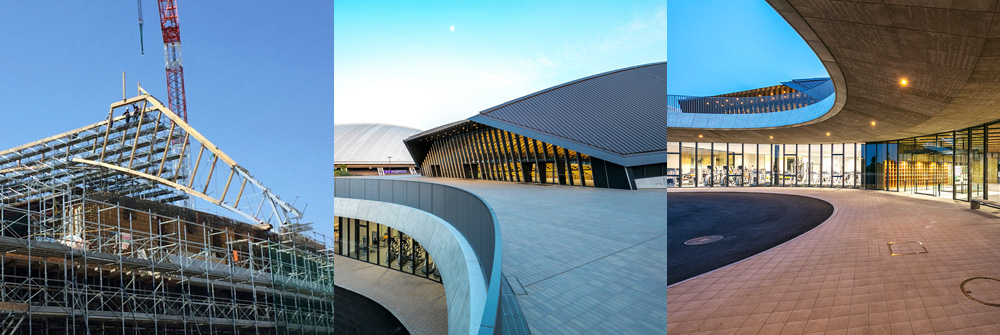

Large roofs that express the spirit and speed of martial arts

What burdened Mr. Tadashi Hamahashi, who was in charge of the design, was how to shape the large roofs that span the main stadium and the martial arts stadium. “The surrounding area is surrounded by mountains near populated areas, and right next to it is the huge Crasus Dome Oita designed by Mr. Kisho Kurokawa. I wanted to adopt a shape that fits well into such scenery. In addition, I would like to express the spirit of martial arts and the speed of sports.” After consideration, I came up with this simple yet beautiful combination of curved surfaces. Its appearance can be compared to that of a Japanese sword, and it is suitable as a place where martial arts competitions are held. In addition, this roof shape can pass off the wind from the south. The rows of roofs, which gradually decrease in volume from the Crasus Dome Oita, are as comfortable as if they had been planned together from the beginning. The formation of the landscape by the buildings was thus successfully accomplished.

Achieve a large span with cedar lumber produced in Oita

At the proposal stage, only the roof frame of the martial arts stadium was made of wood, and that of the main stadium was assumed to be made of steel. However, during the design stage it was decided that both would be made of wood. If you want to build a large span building of this size from wood, using laminated lumber would be the first option. However, laminated lumber was not produced in the prefecture, and the cost did not match. Thus I chose to make it from cedar lumber produced in Oita Prefecture. In the martial arts stadium, cedar lumber is connected, as it is as the frame, but in the main stadium where the span is 70 m, cedar lumber is combined like H-shaped steel and used for upper chords, lower chords, and struts. From the viewpoint of design, this will do. However, the procurement method of lumber stood in the way. The properties of lumber vary. It is difficult to obtain such an amount of lumber with the required properties in a short period of time.

Use the right material in the right place on the assumption of variation of lumber

To overcome this barrier, Mr. Noriaki Yamada, who was in charge of structural design, adopted the method of classifying lumber by properties and using it where it could be used. “We classified the lumber into four types according to the moisture content and Young’s modulus and used each of the types in the right place. For example, in the main stadium, for example, we use lumber with a Young’s modulus of 6.4 or higher because the lower chord is the member on which the most force is imposed, while for the upper chord we use lumber with a Young’s modulus of 4.9 to 6.4 because the upper chord is a member on which not so much force is imposed.” Thus it was possible to procure all the lumber from Oita Prefecture. The Association of Lumber Cooperatives in Oita Prefecture, which supplied the lumber, was also pleased because all the lumber could be used without waste. “Based on the premise of the variability, if you design with fixed specifications, you can use woods much more flexibly,” says Mr. Yamada. When it comes to “the right thing in the right place,” in the main stadium, steel frames were also used at the ends of the arch. This is in order to clear the Fire Resistance Verification Method, and it was also possible to provide a horizontal continuous window. Natural daylight and ventilation are also made possible. “When you open this window and the skylight window, a pleasant breeze passes through the main stadium,” Mr. Hamahashi said.

VPL verification linking structure and design

Another thing to pay attention to when building large wooden spaces with lumber was the joint parts. “Because it is made by connecting short pieces of lumber, naturally there are many joint parts. We have to figure out how to make it reasonably. In this building, we made each arch into a circular arc” (Mr. Yamada). This made the curvature constant, and all joint parts could be made with the same details. And VPL (Visual Programming Language) played a great role in roof designing. “There are a number of members and the overall shape is complex, but the rules of structure are clear. By creating a 3D model that formulates dimensions and shapes beforehand, even if you change the span-rise ratio or the number of divisions of the arch, you can immediately verify the image after the change,” said Mr. Nagata. This made it possible to work out a design in a short time while combining a rational structure with a beautiful shape that evokes spirituality.

MEMBER

- Tadashi Hamahashi

- Deputy Manager, Architectural Group, Design and Supervising Division

- Junichi Nagata

- Supervisor Architectural Group, Design and Supervising Division

- Noriaki Yamada

- Representative: Yamada Noriaki Structural Design Office

Crasus Martial Arts Sports Facility (Oita Prefectural Martial Arts Sports Facility)

Project

members

- Design

- Shuji Nose/Tadashi Hamahashi/Junichi Nagata

- Structure

- Kenichiro Hara/Satoshi Tada (former member)/Noriaki Yamada (representative of Yamada Noriaki Structural Design Office)

- Electrical

- Masaki Michishita

- Mechanical

- Yoshibumi Sekine/Daichi Takano

Work data

- Construction

- Fujita/Suemunegumi Specified Construction Joint Venture

- Site area

- 1,243,400 m2

- Building area

- 14,551 m2

- Total floor area

- 16,125 m2

- Number of stories

- 3 stories above ground and 1 story underground

- Structure

- Reinforced concrete construction partly steel frame/wooden

- Construction period

- From March 2017 to April 2019